Technology

Perfect sound lies in the detail

The Chassis

Our coaxial chassis

In our Art and Nature ranges we use a coaxial chassis with a tweeter made of beryllium and a midrange driver / bass-midrange driver made of magnesium.

Very close to the point source

The tweeter in a coaxial chassis is placed in the acoustic centre of the midrange / bass-midrange driver. This design facilitates perfectly symmetrical dispersion in every direction and brings us very close to the ideal of the point source with simultaneous dispersion from tweeters and midrange / bass-midrange drivers.

The result is a sound with extremely precise spatial imaging and outstanding depth. The ability to place individual instruments is exceptional and we create an audio landscape that offers you an incomparable musical experience.

Simultaneous dispersion from midrange drivers and tweeters

In our pursuit of near perfect sound we place great importance on simultaneous sound dispersion.

That means that the sound produced by the tweeters and midrange / bass-midrange drivers travels the same distance to the listener.

The technical term used for this is constant group delay. We achieve this almost perfectly with our coaxial chassis.

As a result of this simultaneous dispersion of sound you experience in a realistic way not only the arrangement of the instruments within the room, but also the acoustic conditions of the space in which the recording was made.

Beryllium tweeters

What makes beryllium impressive is its unique combination of rigidity and mass. Put another way: the hardness-to-weight ratio is very good.

Its superior speed of sound compared to other materials is another of its advantages.

Beryllium also has excellent self-damping properties.

The sum of these characteristics make it the ideal material for precise and fast tweeters that do justice to every nuance of sound.

The result is an extraordinarily clear, clean sound that brings out every recording’s finest details. As a result of using beryllium tweeters, previously undiscovered nuances and subtleties that used to be hidden become audible.

Magnesium midrange / bass-midrange drivers

Magnesium is an ultra-lightweight metal. It is characterised by extreme rigidity and good internal damping. The cone is thus able to work in an optimally piston-shaped way. Partial vibrations are also significantly reduced by magnesium. The chassis’ decay behaviour also benefits from this lightweight material.

The result is an appreciably clearer, more distortion-free reproduction of midrange frequencies, which enhances the quality of the sound still further.

Our woofer chassis

The woofer used in our Art One.2 is a hand-made woofer with a carbon cone.

Carbon is an extremely lightweight and extremely rigid material – ideal for a woofer chassis.

The woofers are made specifically to our requirements in Germany.

Special chassis fixing

The findings of the finite element method have been implemented in a special way of fixing the chassis.

Instead of being fixed directly on the cabinet, they are now held in a brace with the cabinet by means of an anti-magnetic counter ring on the inside.

By virtue of this extremely solid connection the sound is reproduced with even more clarity and precision.

Resonance-optimised cabinets

Our history is characterised by continuous ongoing development. We have always looked for innovative methods to continually improve the sound quality.

Instruments are producers of sound, while loudspeakers are its reproducers. It is therefore key that speaker cabinets are developed and made in such a way that they neither resonate nor generate their own sounds.

Two different methods have always helped us in the development of resonance-optimised cabinets.

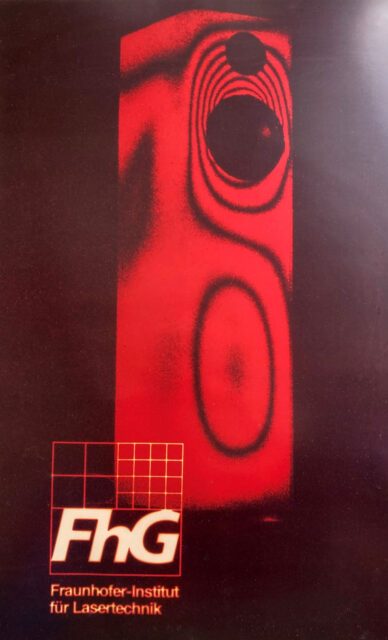

Interferometric

method

Back in 1987, the advantages of a loudspeaker cabinet with its internal chambers clad with mats filled with steel balls were already being investigated – at that time still by ‘Audiodata Elektroakustik GmbH’ – as part of a degree thesis at the Frauenhofer Institute. Using a laser-controlled interferometric method, measurements were taken of the resonance improvement compared to a conventional speaker cabinet.

The mats are made of small chambers that are filled with tiny steel balls. Microscopically small movements of the balls inside the chambers optimise the cabinet’s resonance. This method absorbs the cabinet’s resonance almost completely. The result is a uniquely clear, precise sound, in which all you then hear is the loudspeaker chassis.

Since that study was done, all of our loudspeaker cabinets have been clad on the inside with felt-covered steel ball mats.

Finite element method

In 1996, as part of another degree thesis – at that time still by ‘Audiodata Elektroakustik GmbH’ – the finite element method was used for the development of the timeless classic, the ‘Elance’.

It was a decisive step for the optimisation of loudspeaker cabinets.

As part of a project with crane manufacturer Palfinger, we studied in 2018 – by now in Salzburg – the cabinet of the Art Two using the finite element method.

The aim of this project was to find out what forces the deflection of the chassis cone exerts on the chassis mounting in the cabinet and on all cabinet parts. As a result it was possible to localise any corresponding cabinet deformation and weak spots and then to minimise or eliminate them.

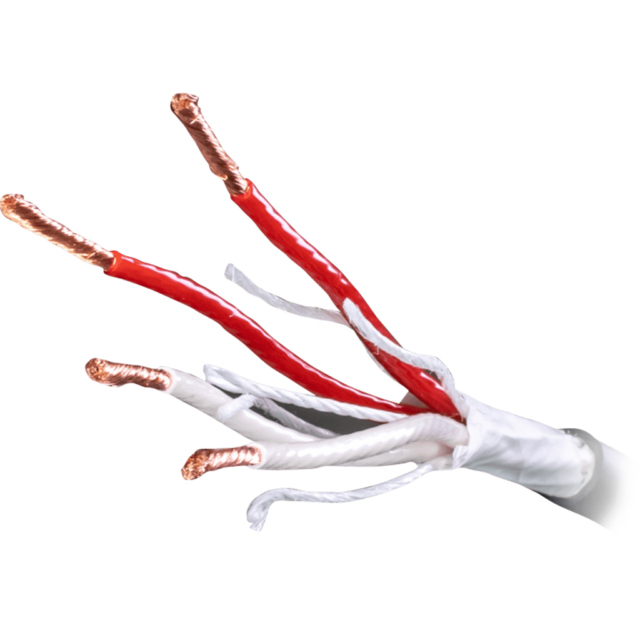

Quality internal cabling

The result of all our endeavours is the LS-CU-4 cable, made especially for us.

Working in close collaboration with a prestigious German cable manufacturer, we have developed an exceptional cable that not only satisfies our extremely high demands in terms of audio quality, but also masters technical challenges in order to provide an incomparable acoustic experience.

Our primary focus was not only on honing the sound, but also on reducing to an absolute minimum any technical stumbling blocks such as the skin effect, the proximity effect or runtime differences in the cable.

The skin effect, whereby low tones flow through the entire strand and high tones flow only on the outside harbours the risk of phase shifts. We have minimised this phenomenon in optimum fashion through the use of numerous thin strands.

The proximity effect describes a loss that can occur in parallel electrical conductors and has a negative impact on the sound. Together with our German supplier, we optimised this problem through an innovative approach to cable design such that the resistance remains uniform as the frequency increases. The choice of insulation material for the individual conductors also plays a decisive role in relation to the sound quality. By using high-quality Teflon as an insulator, we minimise any unwanted effects and thus increase the purity of the sound.

Copper – with its outstanding electrical conductivity – was specifically chosen, as it meets our requirements in audio terms and is a perfect match for our loudspeakers.

The result of all our endeavours is the LS-CU-4 cable, made especially for us.

- Each of the four conductors consists of 322 thin strands with a diameter 0.10mm.

- The conductor material consists of high-purity copper with a purity level of 99.9%.

- High-quality Teflon FEP serves as the insulator in order to minimise any unwanted effects.

- A special polypropylene tape keeps the four conductors physically separated from each other.

This sophisticated combination of cable composition and materials facilitates outstanding resolution across the entire frequency range and thus ensures a peerless audio experience in low, mid and high frequencies.

High-quality audio crossover components

made in Germany and Denmark

All crossover components are made in Germany and Denmark.

We invest a great deal of time and effort into the fine tuning of our loudspeakers. We test and optimise numerous variants and combinations of coils, resistors and capacitors in long, intensive listening sessions.

In this way we determine the best component combinations that give the speaker a perfect sound.

Such a development phase lasts several months, with the objective always being a flawless audio experience.

Only when test listeners and professional audiophiles alike are happy with the result is the loudspeaker deemed finished.

The crossovers are housed in a sealed chamber within the loudspeaker cabinet. Only in that way can it be ensured that no direct sound waves cause the crossover components to vibrate.

Resonance-optimised

audio crossovers

In order to get even closer to the objective of perfect sound, the crossovers are coated with C37 Ennemoser violin varnish.

This varnish is made up of precious natural resins and oils, which are mixed in a special ratio.

Coating the components and crossovers with this special varnish reduces any resonance. As a result the components vibrate less, which leads to a more natural, calmer sound. It becomes clearer – without any discolouration – and appears to be of higher resolution than ever before.